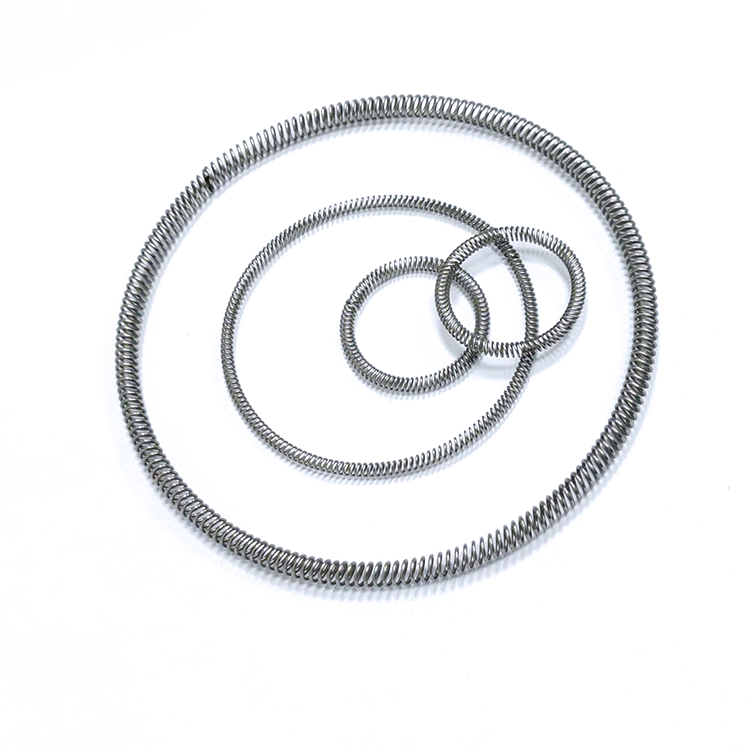

The design process of helical springs is rigorous and meticulous, and many potential influencing factors must be comprehensively evaluated in order to achieve t

When carefully crafting helical springs (coil springs), we need to carefully evaluate many factors to ensure that they are fully suitable and perform well in a

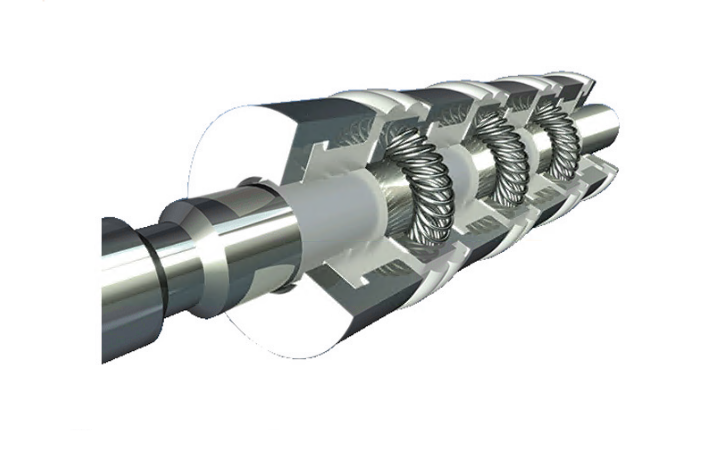

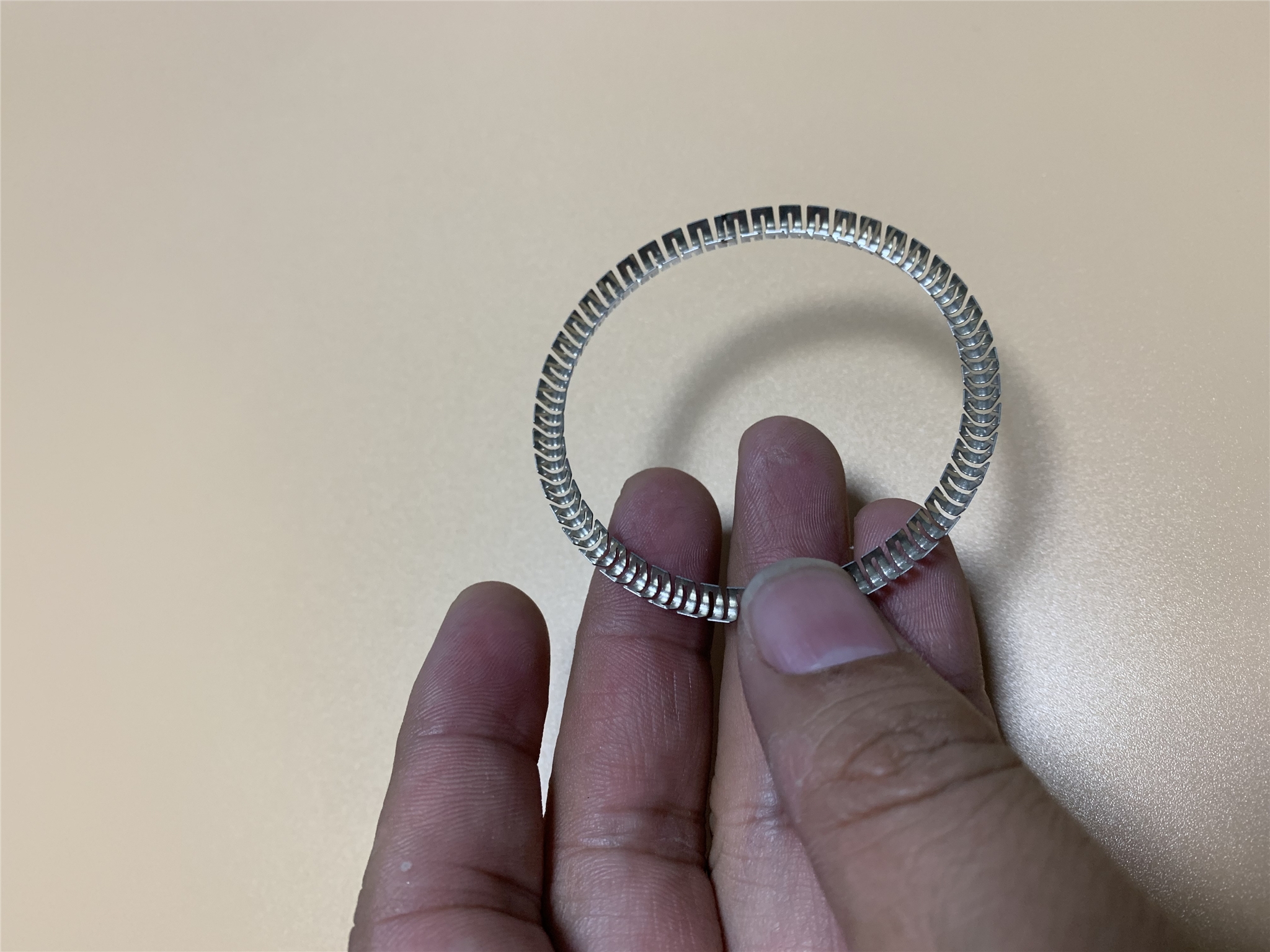

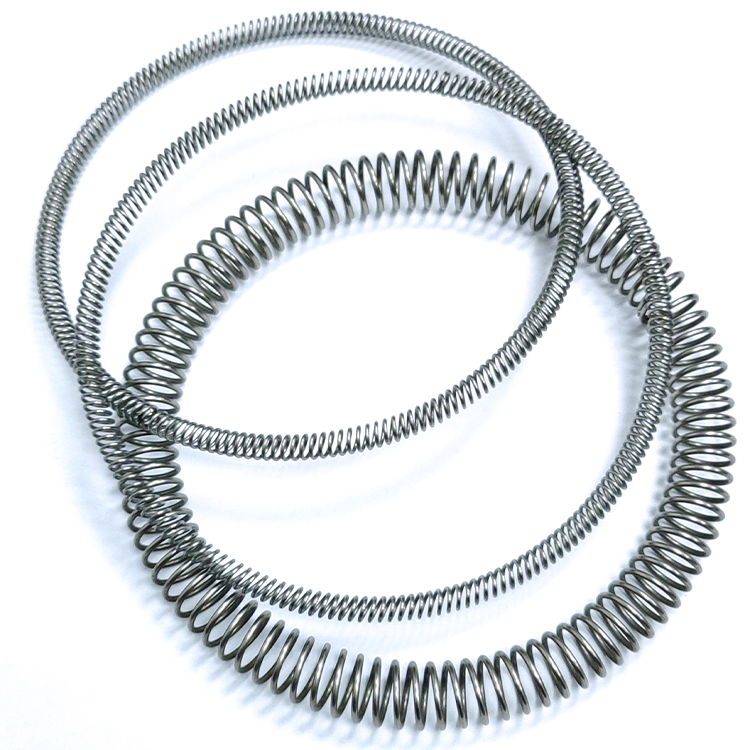

As a widely used EMI shield, canted coil springs are precisely made of steel wire and winding wire and have excellent strength and elasticity.This type of sprin

Canted coil springs are a very practical product in EMI shielding applications. They are usually made of steel wire and wound wire and have high strength and el

Canted coil springs are made from a wide variety of materials, each with its own unique characteristics and range of applications.Therefore, when selecting a ca

As a commonly used mechanical part, canted coil springs are widely used in various types of equipment.In order to meet different application requirements, the m

The materials we select for our canted coil springs are carefully selected to ensure they deliver ideal performance.For example, stainless steel materials have

Canted coil springs are often made of a variety of materials to better correspond to various specific applications.Key considerations in selecting the appropria

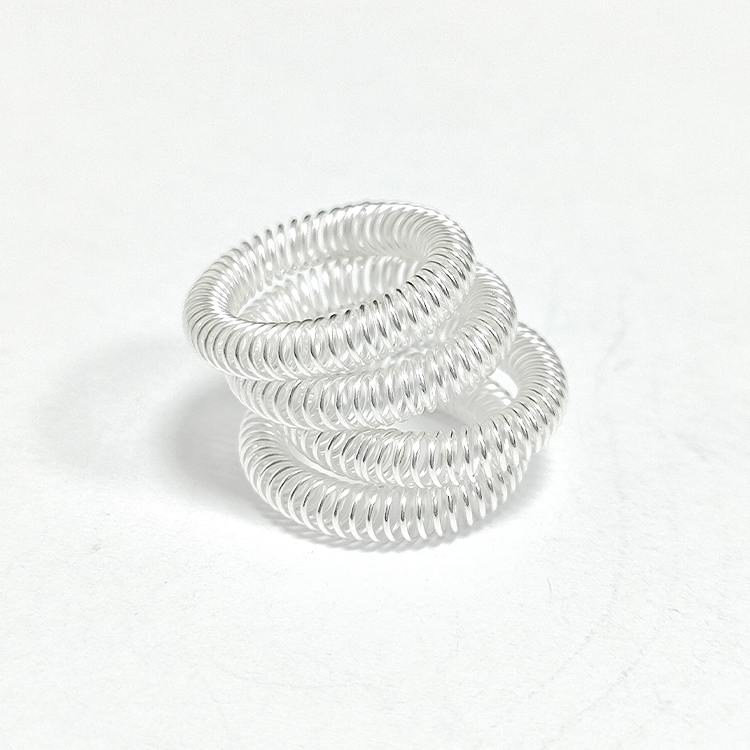

Conductive springs and canted coil springs are two very common spring types, with the main differences being their design purpose and function, as well as diffe

Two forms of springs, conductive springs and canted coil springs, are very common and important in daily life and work.However, to understand the differences be

Conductive springs, such as the Bal Spring® canted coil spring, are designed to manage electrical connections while also providing mechanical support. These

The universal plug spring has been tested and proven to effectively reduce radiation and electromagnetic interference. The universal plug spring can provide mul